MULTi-Cargo FreshBoard

Paper-based food carrier for skin packaging

High-vacuum packaging for longer shelf life of refrigerated goods

High-vacuum packaging ensures maximum shelf life for food that needs to be kept cool. Completely enclosed in film, raw, uncooked food such as meat and sausage products, fish or cheese is reliably protected from air and the escape of liquids. The maturing process of the products is slowed down, significantly extending their shelf life.

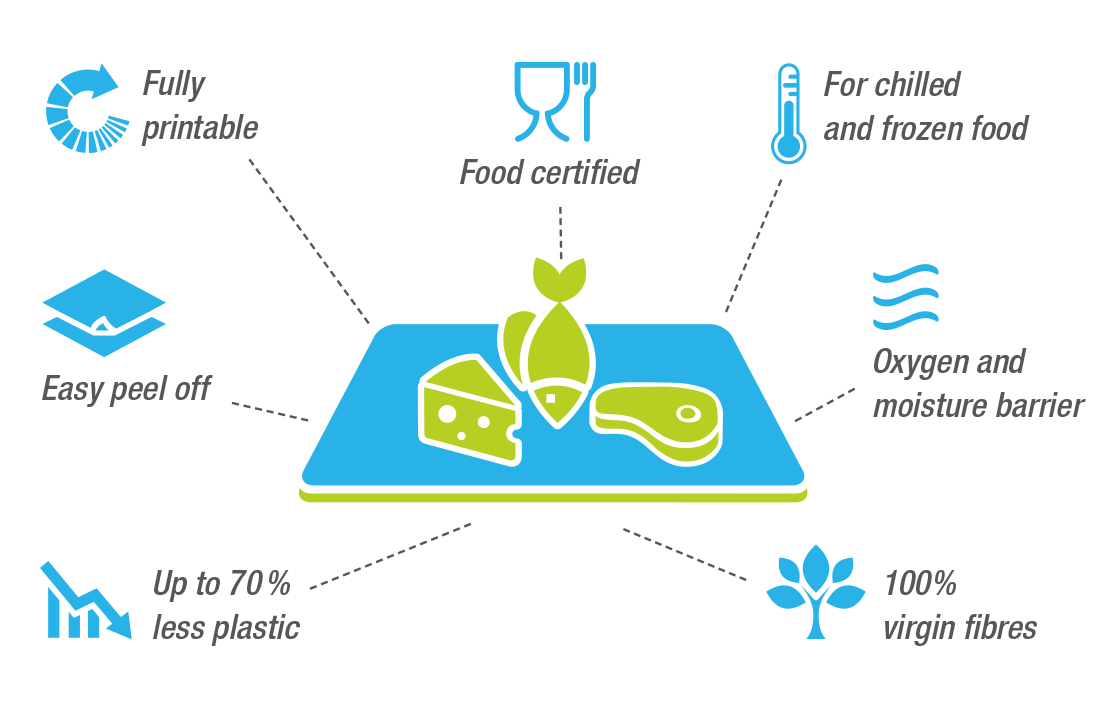

MULTi-Cargo FreshBoard – our cardboard-based carrier plate combines many advantages

By using MULTi-Cargo FreshBoard, a sturdy product carrier made from 100% fresh fibre cardboard, the plastic content of vacuum packaging can be reduced by up to 70%. Thanks to the skin coating on the cardboard base, the climatic advantages of vacuum packaging remain identical to those of comparable full plastic packaging, e.g. with plastic backs or plastic trays. The cardboard coated using the skin process is also protected against moisture inside refrigerated and frozen storage rooms and retains its shape and protective function even in damp external environments.

The stable carrier plate, which can be printed on both sides over the entire surface, offers considerably more information and advertising space than classic saddle riders for plastic packaging. In addition to the possibility of exclusive finishes, e.g. foil embossing, Euro perforation for hanging in refrigerated shelves is also possible.

This combines an attractive appearance at the point of sale with the requirements of high-vacuum packaging.

Skin packaging – freshness guarantee for high-quality food

Fresh foods such as meat, sausage products, fish, seafood, poultry and cheese have a wide range of packaging requirements. Liquids must not leak out and the packaging must protect against external influences (air, moisture, etc.).

![]()

With skin packaging, the upper sealing film fits snugly and without tension around the packaged goods lying on the dimensionally stable carrier. The base, the MULTi-Cargo FreshBoard, is also sealed over its entire surface with a special skin film. Vacuum sealing fixes the product to the board and prevents it from slipping. Whether standing, hanging or lying down, skin-packed goods always make a good impression at the point of sale.

Peel-off corners for easy handling

The reliably sealed vacuum packaging can be easily opened using the specially pre-cut peel-off corner. This allows the product to be easily removed from the packaging despite the vacuum seal. The peel-off corner can then also be used to easily separate the cardboard carrier from the film layer for disposal in the waste paper.

Customised formats for vacuum skin packaging

The format of the MULTi-Cargo FreshBoard adapts to the product and the production line. Like any printed item, the board size is essentially flexible. The only limitations are the requirements and capabilities of the thermoforming packaging machine used and the standard locations at the point of sale.

Advantages at a glance:

- Food-certified backing for vacuum skin packaging

-

Paper-based, sustainable product carrier made from 100% fresh fibres

-

Up to 70% less plastic than comparable vacuum packaging

-

Board can be printed on both sides and over the entire surface

-

Skin film as a barrier against oxygen and moisture

-

Peel-off corner for easy opening

Your contact person

Aron von Lieres

Sales and Service

Tel.: +49 5136 8004 511

kontakt@multi-cargo.com