Load Safety

Anti-Slip Mats Based on Cardboard or Rubber

Article in MM-Logistik of 11 February 2013

Anti-Slip Mats Based on Cardboard Secure Loads Sustainably

During contact between cargo and load surface, so-called microtoothing creates friction between load surface and cargo. Anti-slip mats based on cardboard, which can be disposed of as environmentally friendly waste paper, are an interesting alternative to those made from rubber.

Rubber anti-slip mats are used to ensure load safety in accordance with §22 StVO (German road traffic regulations) and according to standard practice as per VDI 2700. These mats are often made from used tyres. The disposal of the rubber mats once discard criteria are reached involves relatively high costs. This is one of the reasons why the necessary replacement of the mats is often delayed or slip-inhibiting mats are not used – at the expense of safety and efficiency.

The load safety of for instance boxes stacked on pallets is everyone’s business: From the lorry driver via the representative to the senior management of the consignor/sender.

Good load safety is ultimately not expensive

“Attention! Overturned lorry … cargo fell off … traffic down to one lane …” – these and similar announcements are a daily nuisance and a danger for motorists. Accidents of this kind regularly lead to tailbacks stretching for miles, delays in deliveries or failure to meet deadlines. The scale of the accidents is often exacerbated by non-existent or inadequate load securing.

This inadequate or non-existent securing of the load is often the trigger that leads from an everyday traffic situation to an accident. But why? Good load securing is not expensive compared to the hundreds of millions of Euros personal injuries and material damages are causing the economy every year.

Anti-slip mats based on cardboard with slip-inhibiting coatings are good value

Anti-slip mats based on cardboard have long become an established alternative to load securing with rubber mats. They are cost-effective, free from plasticisers and are made from 95 % renewable and recyclable resources. Paper, card or corrugated board offer the sustainable base for optimum pallet and transport safety. “Green products” have been talked about for years in all industries. Nordpack takes on responsibility in load safety and chooses a recyclable and tested product based on cardboard with their Safety-Grip anti-slip mats.

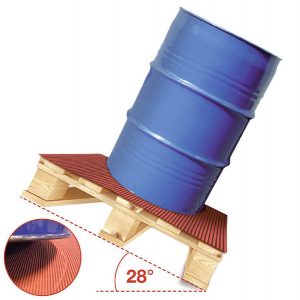

The load safety range Safety-Grip was developed with the different requirements of load, pallet and unit safety in mind (drums and canisters), based on decades of experience in paper manufacturing and processing. This resulted in a recyclable anti-slip mat based on cardboard in combination with a special patented and slip-inhibiting coating.

The load safety range Safety-Grip was developed with the different requirements of load, pallet and unit (drums and canisters) safety in mind, based on decades of experience in paper manufacturing and processing. This resulted in a recyclable anti-slip mat based on cardboard in combination with a special patented and slip-inhibiting coating.

The material properties of the two components complement one another and create a combination that allows for optimum handling. The inherent stiffness of the cardboard used allows for easy placing and the silicone coating results in slip-inhibition with good coefficients of sliding friction. Depending on requirements and securing needs, Safety-Grip products are anti-slip coated either in strips or all over and can be used as intermediate or base layer on the pallet or under the cargo. Nordpack product securing systems are even used with loading aids with steel runners.

Clean, unused anti-slip mats are often used for transportation of goods

After successful use, Safety-Grip anti-slip mats can be disposed of cheaply as environmentally friendly waste paper. They are manufactured in CO2 neutral plants. In addition, single use ensures that a clean, unused anti-slip mat with maximum performance is used for every shipment. This is appreciated by transport police and authorities like the Federal Office for Goods Transport alike.

Fact is: Load securing anti-slip mats from the Safety-Grip series achieve coefficients of sliding friction in accordance with VDI 2700 part 9 and German industry standard DIN EN 12195-1 in common combinations of materials. In addition, users of Safety-Grip products from Nordpack achieve the greatest possible benefit at low cost and with low material input.

* Sven Mehrmann is product manager Team Multi-Cargo at Nordpack GmbH, 30916 Isernhagen

Safety-Grip, the “red load securing device” is available as strips or as all-over sheet material in strengths of 0.4, 0.8 and 2.2 mm.

Safety-Grip, the “red load securing device” is available as strips or as all-over sheet material in strengths of 0.4, 0.8 and 2.2 mm.

Tipping tests are the tests that will be a crucial requirement in the area of load securing in the future.

Source: http://www.mm-logistik.vogel.de/distributionslogistik/articles/394044/?cmp=beleg-mail