Securing cargo in transport

The Little Load Safety Helper

Article in TRANSPORT + LOGISITK of 29 September 2009

by Stefan Klein

LOAD SAFETY – Securing cargo in transport is really important and is therefore explicitly mentioned in the ADR treaty. In practice, adequate load securing requires a lot of effort – efficiency is required.

Friction is the friend of every shipper and haulier engaged in load securing. It counteracts the slipping of the load. To date it hasn’t been easy to assess the value of this “natural” load securing correctly. There are a number of load safety calculators online or on CD which work out the number of straps needed when input with a variety of vehicle and load parameters and thus avoid the need to work out the complicated formulae for oneself. But an important or even the deciding initial value for these calculations is the difficult-to-determine coefficient of friction µ that indicates the degree of “microtoothing” between the bottom of the cargo and the load surface.

The higher the coefficient of friction, the higher the friction force that absorbs part of the inertial and centrifugal forces during movement changes. For full load safety, the securing force of at least the difference between inertial and friction force must be applied with straps or taken on by the vehicle structure.

![]()

Sliding instead of static friction

In Germany, the coefficient of friction refers to sliding or rolling friction, describing the friction of a moving body according to the dynamic principle. Therefore, the term coefficient of sliding friction is often also used. Another form is static friction which is generally higher than sliding friction because more force is needed to put a body in motion than to keep it moving.

Coefficients of sliding friction have been published for a number of loading surfaces/carriers according to DIN EN 12195-1 and VDI standard 2700 et seqq. Thus, the value between “friction partners” lorry with non-slip floor and wooden Euro pallet is 0.25. The coefficients of friction not only depend on the surface qualities of the respective materials, but also on the state of the load surface: If this is wet, covered in grains of sand or even stained with oil or grease residue, friction is reduced drastically.

The published coefficients of sliding friction are general, rounded values between the sliding partner pairings that are most common in transport. Should a shipper or carrier require exact values for their specific cargo and vehicles, then this will require “specific examination between the different materials in the various states,” according to the load safety group at TÜV Nord. The association of German engineers VDI has recently presented a draft standard dealing with the scientific procedures for determining the coefficients of friction in the 12-page part 14 of VDI standard 2700.

But a company can carry out these tests themselves – especially for the friction between load carrier and the packaging on it, which is just as important as that between load carrier and vehicle floor. The equally new DIN EN 12195-1 states: “A simple procedure for determining the coefficient of friction µ consists of inclining the load surface with its respective cargo and measuring the angle at which the cargo begins to slide.” Five tests have to be carried out under practical and realistic conditions. The highest and lowest result will be disregarded. The accepted friction is the mean value of the three results used. The report must state whether the result is valid for dry and/or wet conditions.”

In this way, for example, the company-specific coefficient of friction between a pallet type used and the material of a filled big bag can be established. The relevant literature generally states the value as µ = 0.3.

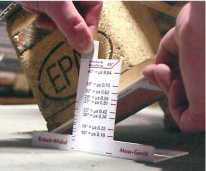

![]()

Measuring device from cardboard

The innovators at Multi-Cargo took this as inspiration to develop a simple “sliding angle measuring device” from cardboard. Once the sliding angle has been set under a pallet tilted with a forklift, the coefficient of friction can also be seen straight away. “Naturally, safety precautions have to be taken to avoid cargo falling off the load surface,” Multi-Cargo’s product developer states. The measuring device can be used in such a way that no fingers get under the load range.

The innovators at Multi-Cargo took this as inspiration to develop a simple “sliding angle measuring device” from cardboard. Once the sliding angle has been set under a pallet tilted with a forklift, the coefficient of friction can also be seen straight away. “Naturally, safety precautions have to be taken to avoid cargo falling off the load surface,” Multi-Cargo’s product developer states. The measuring device can be used in such a way that no fingers get under the load range.

For field tests, random sampling and monitoring the coefficient of friction between load surface and cargo, until now the so-called “Königsberg friction block” proved useful. The one kilogramme cuboid can be equipped with different materials on its four long sides. It was developed years ago by a group of experts at the Königsberg Ladungssicherungskreis (load safety circle). The friction block is attached to a precision spring balance and simply pulled over the base that is to be measured. The scale of the balance indicates the coefficient of sliding friction. Tensile tests carried out with this 115 Euro friction block only differ from those carried out extensively in laboratories by a maximum of ten percent. However, the results calculated in this way may not be used as evidence in court; they are only suitable to “indicate the friction present in situ.” Nordpack considered the long-serving friction block not accurate enough for their tensile tests.

Reading the value when the measuring device is beginning to slide – e.g. 600 g = coefficient of sliding friction µ 0.6

They developed their own “coefficient of friction measuring device” in form of a steel sheet. A variety of sections of material can be inserted under this. “The flatter shape in comparison with the friction block allows for more even pulling,” the product manager explains. The bigger friction area of about 8 by 20 centimetres complies with DIN EN 8285 standard. Multi-Cargo offers the measuring device at a cost price of 75 Euros. Demand is high especially from driving schools.

![]()

Lashing down requires force

Friction force is especially important for load securing by lashing down. The complex procedure, also called traction, requires the load securer to bring to bear manual force of 50 daN on the ratchet handle – which converts to about 50 kilogrammes. Experts have long criticised that 50 daN can only be achieved by a minority of lorry drivers due to the necessary physical effort.

Friction force is especially important for load securing by lashing down. The complex procedure, also called traction, requires the load securer to bring to bear manual force of 50 daN on the ratchet handle – which converts to about 50 kilogrammes. Experts have long criticised that 50 daN can only be achieved by a minority of lorry drivers due to the necessary physical effort.

“In day-to-day use, ratchets can often only be pressed upwards so you cannot bring your own body weight to bear,” load safety expert Sigurd Ehringer explains. In order to achieve 50 daN with a standard commercial ratchet, a great physical effort is necessary (see left picture above). With “SpannControl” tightening the strap becomes child’s play: only 15 daN of manual force are necessary (see right picture above).

![]()

Anti-slip mat standard is binding

The VDI standard 2700 Part 15 “slip-inhibiting materials” is now binding. This, anti-slip mat manufacturer Marotech points out. The standard for rubber granulate mats prescribes minimum values for tensile strength (0.6 Newton per square millimetre) and for elongation at break (60 per cent). The use of sub-standard rubber building protection mats as anti-slip mats is thus prohibited. Buyers and logistics managers have to implement load safety to the latest technical standards. If not, they can be held accountable after an accident involving personal injuries: In this case, the police will collect as evidence any anti-slip mats that may have been used. Anti-slip mats are becoming an ever more popular means of load securing with coefficients of friction of mostly 0.6 µ.